At Tokyo Electron Ltd. (TEL), we revolutionized wafer production by introducing cutting-edge automation and real-time tracking solutions. Through automated purchase order processing and seamless wafer tracking, our innovative approach significantly increased operational efficiency, moved for better logical order, and ensured strict compliance with regulatory standards. The result? Faster, more accurate, and highly optimized production processes that set a new benchmark in the semiconductor industry.

About Us

Tokyo Electron Ltd. (TEL), headquartered in Japan, is a leading multinational corporation specializing in semiconductor and flat panel display production equipment. Renowned for its cutting-edge technology and innovation, TEL provides advanced solutions that enable manufacturers to produce integrated circuits and high-performance display panels. Serving semiconductor manufacturers, technology innovators, and electronics leaders worldwide, TEL offers a unified approach to precision manufacturing, compliance, and efficiency.

With a robust portfolio of automated systems and real-time tracking technologies, TEL has established itself as a trusted partner in the semiconductor industry. The company's annual revenue is approximately $12 billion USD , reinforcing its position as a market leader. Its unwavering commitment to innovation and exceptional service has solidified its position as a leader in the market. TEL’s advanced solutions empower businesses to optimize production processes , enhance product quality, and maintain a competitive edge in the fast-evolving world of technology.

Tokyo Electron Ltd. relied heavily on manual systems to process purchase orders, which introduced several challenges. The manual nature of the process led to significant delays in order fulfillment, as errors in data entry and miscommunication between departments resulted in incorrect or delayed orders. This not only disrupted the production timelines but also increased the risk of stock shortages, which in turn affected wafer manufacturing schedules and the ability to meet client demand. The lack of automation and real-time updates further compounded inefficiencies, creating a bottleneck in the supply chain and raising operational costs.

Tokyo Electron Ltd. faced significant delays and errors due to their reliance on manual systems for processing purchase orders. The manual processes led to miscommunication between departments, incorrect orders, and delays in production. This disrupted production timelines, raised the risk of stock shortages, and affected the company's ability to meet client demand.

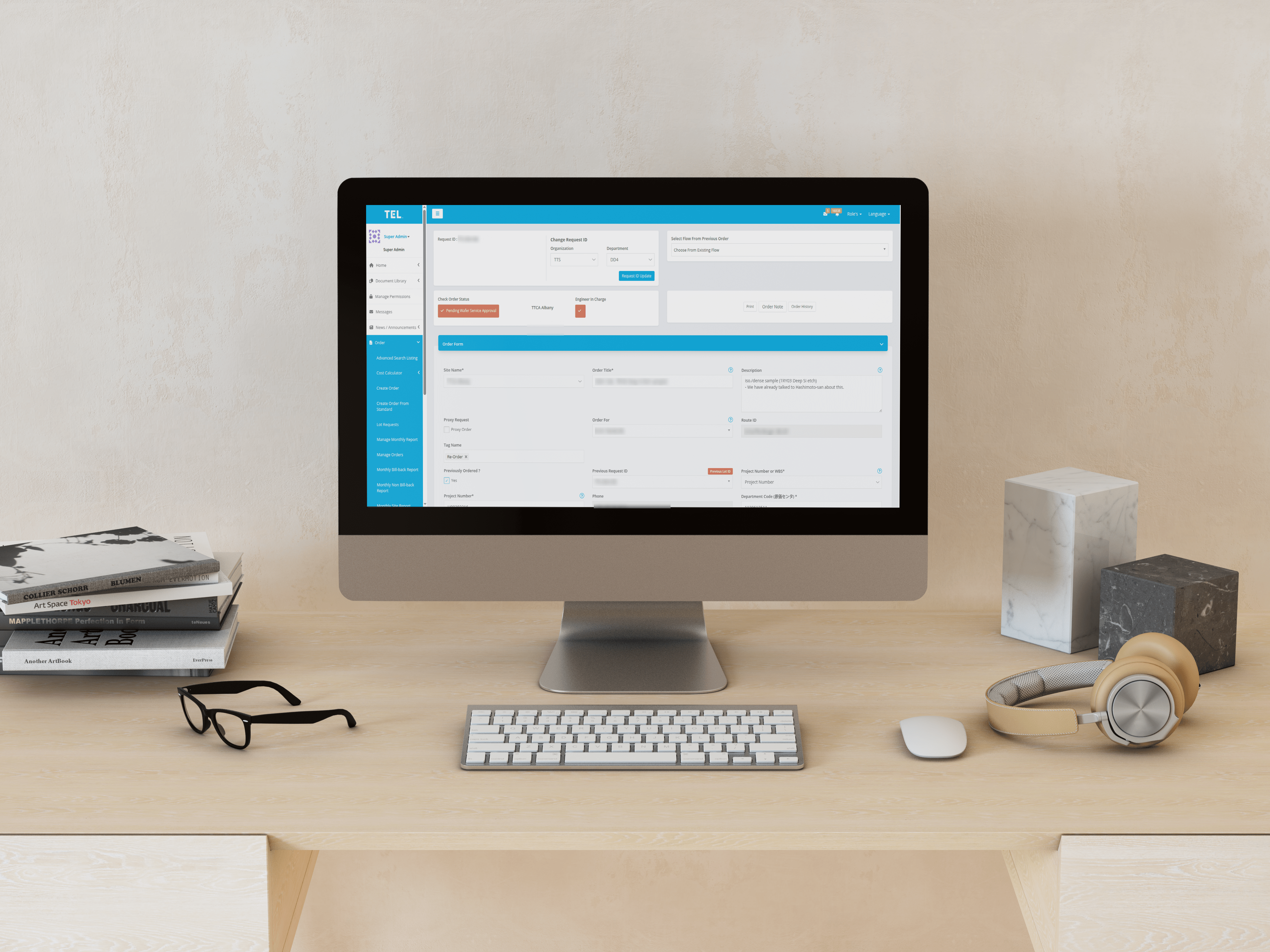

To address this, we implemented the solution that streamlined the order initiation process, automatically triggering wafer production as soon as purchase orders were received. The system minimized manual errors and provided real-time updates, accelerating production timelines and reducing bottlenecks. Additionally, we developed a centralized processing module using CakePHP and MySQL to fully automate the workflow, ensuring smooth transitions through various process stages managed by different departments and engineers—without human intervention.

The automation of purchase order processing resulted in faster production cycles, fewer errors, and reduced delays. With improved accuracy and speed, TEL was able to meet client demand more effectively, enhancing overall operational efficiency and lowering costs across the supply chain.

With operations across multiple international locations, TEL struggled to maintain seamless communication. The lack of a unified system for real-time updates and information sharing led to misaligned priorities, operational disruptions, and slow decision-making, impacting production efficiency.

To address these issues, we implemented a suite of real-time communication and collaboration tools across TEL's global branches, powered by Box cloud-based communication platform. This solution allowed teams to communicate more effectively and share important updates instantly, ensuring better coordination and secure interactions between branches. Furthermore, we provided centralized real-time chat functionality for users to communicate on individual orders and globally between users, utilizing Node.js and Socket.io.

The implementation of real-time communication tools greatly improved coordination and collaboration across TEL’s international teams. The streamlined communication process led to quicker decision-making, more efficient production processes, and enhanced overall operational performance.

The lack of an integrated wafer tracking system created challenges for TEL, leading to inaccuracies in wafer status, inventory records, and decision-making. The absence of real-time visibility hindered transparency and slowed the identification of bottlenecks or quality issues, impacting production timelines and quality control.

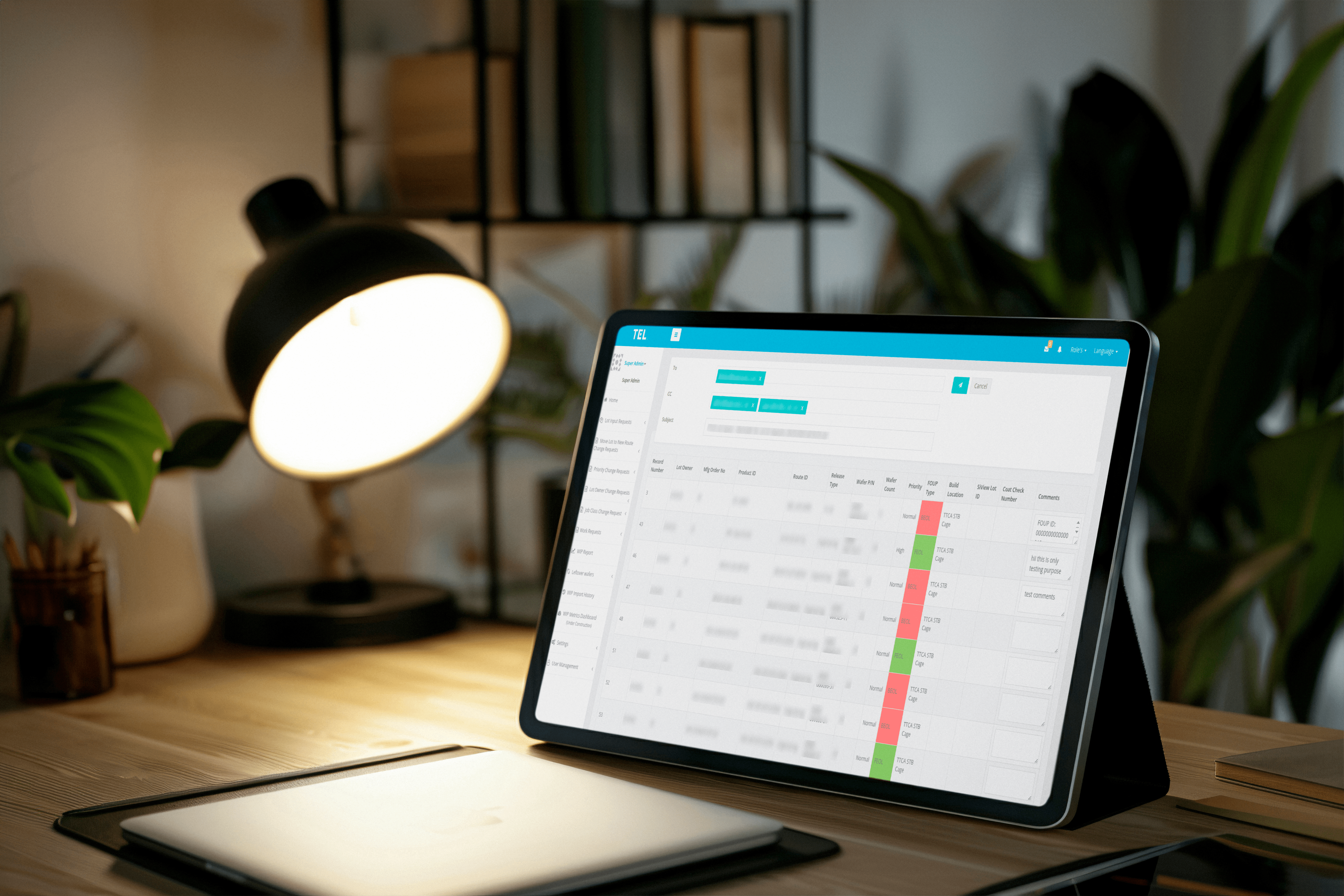

We implemented the Wafer Tracking Module, part of the Sample Wafer Service (SWS), clarified and restructured for clarity for precise monitoring of wafer numbers and their statuses across production stages, improving data transparency and accuracy. Additionally, we provided a centralized module to track wafer stock within the same site or across multiple sites (including different countries). Real-time push notifications were implemented using Socket.io, to keep all stakeholders updated.

With the wafer tracking module in place, TEL achieved greater accuracy in inventory management and better visibility into wafer statuses. Real-time data enhanced decision-making, ensuring more efficient production workflows and improving overall transparency in operations.

TEL faced compliance challenges due to manual processes for notifying regulatory bodies about lot IDs and production milestones. These manual processes often led to delays or inaccuracies in meeting regulatory requirements, increasing the risk of non-compliance and operational inefficiencies.

Automated Notifications and Lot ID Synchronization We integrated an automated system that triggered notifications when lot IDs were assigned. The system also automatically extracted and updated lot IDs from emails, ensuring consistent and current information across TEL’s platforms. Integration with CNSE (Customer Notification of Significant Event) system ensured regulatory compliance was streamlined. CNSE is a formal notification issued by a semiconductor manufacturer to its customers when a significant event occurs that could impact the quality, reliability, or delivery of a wafer lot.

Additionally, we automated the reading of CNSE system emails to manage lot IDs and stock records Real-time push notifications—powered by Socket.io—alerted users based on key actions, further enhancing compliance and operational efficiency.

Improved Compliance, Reduced Errors, and Enhanced Data Consistency Automating compliance notifications and synchronizing lot IDs significantly improved regulatory adherence and reduced manual errors. The streamlined system provided all stakeholders with accurate, up-to-date information, enhancing operational efficiency and data consistency across TEL’s operations.